Page added on June 25, 2017

Albert Bates: Concrete Solutions

“We want to take the atmosphere back to its pre-industrial chemistry as quickly as possible. For that, we have biocomposites.“

We screen grabbed these images off earth.nullschool.net when we were looking at Tropical Storm Cindy on June 19. The top image shows Earth’s oceans. Red is hotter than normal. Blue is colder than normal. The Polar seas are colder than usual because of all the fresh ice water from melting glaciers and ice shelves.

The lower image is the same moment, looking at the land masses too. There are simultaneous heat waves in North America, S. Europe, Africa, the Middle East, India and parts of China, setting temperature records for the date, all the way around.

Kathleen Draper is US Director at Ithaka Institute for Carbon Intelligence. In addition to editing The Biochar Journal, the leading on-line biochar magazine, Draper researches carbon intelligent cities; climate farming: nutrient recycling and GHG reduction in livestock farming; biochar characterization and optimal usage recommendations; closed loop biochar production and use modeling; ecosystem remediation; land management and landscape design. She has worked with Cornell University to model the Triple Bottom Line impact of Combined Heat & Biochar unit at the urban aquaponics greenhouse in Central New York.

Working with the Rochester Institute of Technology, she developed the Filtration to Fertilizer strategy using biochar first to harvest nutrients in effluents from food and beverage industries — including rentals to tofu shops — and then sales of nutrient-saturated char as a soil amendment/fertilizer for greenhouse crops. She is also working with RIT on the use of biochar in sustainable building materials, packaging materials, filtration media for the food industry and heat recovery options for the Kon-Tiki kiln technology.

A few days ago Kathleen Draper penned to her blog:

Last week I visited a small slice of heaven; The Farm in Summertown, TN. The Farm is the oldest intentional community in the country* and has been home to Albert Bates, author of The Biochar Solution amongst other books, for decades. Biochar experimentation at The Farm spans the gamut from soil amendment to building material to humanure additive which then moves over to worm bins for some final processing. Just walking around the various natural buildings and permaculture filled ambiance was enough to inspire, but actually getting my hands dirty making biochar plasters, cement mixes, bricks, filtration devices with other like-minded folks was soul boosting. We visited a nearby farmer that feeds his livestock (pigs, goats, poultry) an earthy blend of biochar mixed with lightly fermented whey and grains which they gobbled up greedily. We used rather grand outhouses that mitigated odors and reduced nutrient leaching with a blend of biochar and sawdust. And we shared stories of our mutual journeys, lessons learned and best practices along the biochar continuum. What I really enjoyed about this experience, especially compared to attending biochar and other related conferences which tend to pack an enormous amount of information into back-to-back 15–20 minute sessions all day long for 3 days, was the more relaxed pace, the ability to get to know everyone there and hear about their own particular biochar experiences. The other fun part was leveraging everyone’s tools and backgrounds to take certain ideas further — such as the chardboard paper which I wrote about nearly 3 years ago. Albert had a contraption that was able to measure the electromagnetic shielding of the chardboard which was pretty substantial, roughly 90% reduction! For those of you that have the time and desire to experience truly sustainable living, I highly recommend a visit to The Farm. Staying in the Fairy House, a cozy earthbag building with a living roof provides the quietest sleep you could ever dream of….

* If you don’t count Sabbathday Lake Shaker Village (1782), Celo (1937), The Vale (1940), Twin Oaks (1967), or most of the Hutterite Colonies, Bruderhofs, monasteries, or ashrams in North America. — editor

We liked having Draper here for the workshop but can’t let her escape with just this short report to the public domain. She and Dr. Hans-Peter Schmidt at the Ithaka Institute in Switzerland brought to our course a wealth of information on the practical applications for biochar when removed from the agricultural sphere. They are co-authors, with Ute Scheub and Hailko Pieplow, of Terra Preta: How the World’s Most Fertile Soil Can Help Reverse Climate Change and Reduce World Hunger.

Hans-Peter beamed into the workshop via Skype and together with Kathleen provided a picture of a new realm of biochar that we had been nearly unaware of — as biochar concrete, or “char-crete”

Cementing History

| Pantheon Oculus, Rome (126 CE) |

Firstly, there is a global problem with concrete and it is getting bigger. The most important part of concrete is Portland cement, the binding agent made from pulverized limestone (calcium oxide) and clay (silicon oxide), heated together at high temperature (2700F).

The discovery and refinement of Portland is a cautionary modern tale of the intersection of materials and manufacturing at the dawn of the fossil fuel era. The Romans and Chinese had millennia ago discovered that gypsum and lime could be mixed with pieces of rock, sand, ceramics or rubble to form a hard material that would hold up to weather, or even set up underwater for dams and bridgework. Roman concrete, developed from 150 BCE, is durable due to its incorporation of volcanic ash and cinders (pozzolana), which prevents cracks from spreading. After the famous fire of 64AD, Nero rebuilt much of Rome with brick-faced concrete. The Pantheon in Rome, with its 142-foot coffered dome and oculus, is an example of Roman concrete construction still standing after 2000 years.

Lime is a powder that wants to be a rock. It has a million-year memory. Formed as the aggregated dust of seashells on an ancient sea-bed, limestone (CaCO3) gets unpacked from its bed in some quarry, hauled by truck to a kiln, and baked at >1500°F. The burn drives off CO2 and leaves behind a powder (CaO), called burnt lime or quicklime.

Quicklime (calcium oxide) is a white, caustic, alkaline, crystalline solid at room temperature, but feeling an urge to go back to rock, it will draw CO2 from the air unless slaked with water. Slaked lime is what the Romans and Chinese used for mortars and plasters. It is what Michelangelo in 1511 spread across the ceiling of the Sistine Chapel and painted the image of God into. In the 1820s scientists learned that when heated to >4,000°F (2,200°C) it emits an intense glow. That feature was used broadly in theater productions before electric lighting — limelight.

As it slakes, quicklime releases heat by the following equation:

CaO (s) + H2O (l) ⇌ Ca(OH)2 (aq) (ΔHr = −63.7 kJ/mol of CaO)

When limestone is kilned to make lime for mortar or cement 1.8 tons produces 1 ton of CaO. The missing 0.8 goes to the atmosphere as CO2 and a few trace impurities. China is by far the world’s largest producer, burning enough rock to produce around 170 million tons per year. The United States is the next largest, with around 20 million. Worldwide, lime kilns send about 225 million ton of CO2 to the atmosphere. File that number a way for a moment.

If you add an atom of carbon to quicklime in the presence of oxygen, you get limestone and water.

Ca(OH)2 + C + O2 = CaCO3 + H2O

That limestone molecule can take a much-deserved rest. It has now completed a full revolution on the wheel of life and rebirth.

Suppose that, instead of leaving it to chance, we supply lime with carbon? One easy way to do that would be to mix biochar with cement and let it harden in the open air. You could replace sand in concrete or mortar. This is convenient because construction-grade sand is getting harder to come by and is experiencing rising demand (and price).

But here is the kicker. The resulting concretes or mortars have improved:

- Weight (biochar is significantly lighter than sand)

- Compression strength

- Flexural strength (MOR)

- Curing (soaking the carbon into the lime)

- Capacity to absorb CO2/NOX

- Electromagnetic shielding

- Fire resistance

- Insulation

- Humidity control

- Indoor pollutant control (dust, pollen, chemicals).

Run the Research

What does the research say? Choi et al (Mechanical Properties of Mortar Containing Bio-Char From Pyrolysis, 2012) tested char-cretes at 5%, 10%, 15%, 20% biochar and found:

- All biochar admixtures had less weight loss due to moisture evaporation. Mortar mixes with char have better water retention. This may lead to improved strength. “In this way, biochar seems to play a role as a self-curing agent.” • The workability of mortar decreases as the percentage of biochar increases. • 5–10% biochar replacement is similar to 20% replacement with fly ash (the toxic residue of cement making and other industries). • Up to 5% biochar shows an increase in compression strength.

A study by Restuccia et al, Promising low cost carbon based materials to improve strength & toughness in cement composites (2016) tested the mechanical properties of cement using biochar made from coffee powder (unroasted discards) and hazelnut shells.

- All char additives outperformed control bending strength, compression & fracture energy. • Coffee powder did better on compression tests. • Hazelnut shells did better on flexural (MOR) and fracture energy tests. • Hazelnut shells’ irregular morphology creates “perfect bond with surrounding matrix.” • Coffee powder has higher silicates which could work as an accelerator helping to speed up the hydration process. It stabilized at 7 days.

A study by Khushnood et al, Carbonized nano/microparticles for enhanced mechanical properties & electromagnetic interference shielding of cementitious materials (2016) tested mechanical & shielding properties of cement using peanut shells and hazelnut shells at 6 different concentrations.

- All char additives outperformed flexural strength of control (2.96 MOR). • Hazelnut shells optimized at .25% (5.44 MOR). • Peanut shells optimized at .25% (5.43 MOR). • Fine aggregates increased fracture toughness.

Does char-crete remove CO2 from the atmosphere? Not directly, although using sources like peanut shells and coffeebean discards that would otherwise go back to the atmosphere as CO2 or CH4 interrupts these (natural) emissions and entombs them for a very long time. However, char-crete does remove other greenhouse gases directly.

A study by Tommaso et al, NOx Adsorption, Fire Resistance and CO2Sequestration of High Performance, High Durability Concrete Containing Activated Carbon (2016) found dramatically decreased levels of NOx (-66%) in addition to fire resistance.

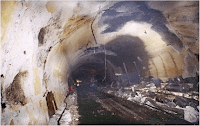

Hans-Peter Schmidt points to concrete fire resistance as more important than most people realize. In the 1999 tragedy on the autobahn through Mont Blanc, 39 people died when a Belgian transport truck carrying flour and margarine caught fire in the tunnel. The fire burned for 53 hours and reached temperatures of 1,000 °C (1,830 °F), mainly because of the margarine. While it is unlikely biochar in tunnel cements or plasters could have filtered air quickly enough to save the lives of those who suffocated from the toxic smoke, we can at least say that the repairs to the tunnel afterwards would have been easier had fire not damaged the concrete of the tunnel.

If just one percent of the sand going into the 25 billion tons of new concrete each year were replaced with biochar, 250 million tons of biochar would be sequestered. With a carbon content of 82–98 percent, that biochar is the CO2 equivalent of 738- 882 million tons per year (205–245 MtC). At present rates of emissions, we’d need to sequester 5.6 billion tons of carbon (GtC) per year just to get to carbon neutrality, 25 times more than this example. Alternatively, the biochar industry could raise its ambition and replace 25 percent of construction sand worldwide with char-crete.

Sources of unregulated waste biomass now in the process of becoming greenhouse gases on their own are literally as vast as the sands of the Ganges. In many places, they will pay you to take them.

Of course, our goal with biochar is not neutrality but drawdown. We want to take the atmosphere back to its pre-industrial state as quickly as possible. For that, we have biocomposites.

Biocomposites

A “composite” is when two or more different materials are combined together to create a superior and unique material. The prefix, “bio,” means that the composite takes natural fibers including wood or non-wood (e.g. leaves and grasses) and blends them with a matrix (binder) made from either renewable or non-renewable sources (lime, clay, plastics, old tires).

Zhao et al evaluated biochar’s impact on hot-mix asphalt when compared to carbon black and carbon fiber (Lab Investigation of Biochar-modified Asphalt Mixture, 2014). Switchgrass biochar was blended at 10% by weight of the asphalt. The study found that bending strength in asphalt normally decreases in temps ranging from 300C — 500C, then increases above 500C, but biochar reduces that temperature susceptibility in asphalt binders. Biochar also showed the highest rutting resistance, meaning it was less often to need replacement because of damage.

1.6 trillion tons of asphalt is poured every year. At 10 percent biochar, that industry would use 160 billion tons, or 89 GtC. That hits the 5.6 GtC net neutrality goal with 83.4 GtC left to be applied to legacy greenhouse gas drawdown. If drawdown at that rate were begin in 2018, carbon dioxide in the atmosphere could be returned to 300 ppm by 2026 (even accounting for the ocean feedback mechanism).

But wait, there’s more.

In 2016 DeVallance et al investigated hardwood biochar as a replacement for wood flour in wood-polypropylene composites. Wood-polypropylene composites are used in building construction, automotive and consumer products. The study combined biochar at rates of 5%, 15%, 25%, and 40% by weight with wood and plastic to make alternative composites to traditional wood-plastic composites. The findings:

- All biochar rates increased flexural strength by 20% or more • Tensile strength was highest with 5% biochar • Tensile elasticity was highest with 25% and 40% biochar • Water absorption and swell decreased • Biochar additions showed improved thermal properties.

All this academic research is good, but it hardly matters until it gets out of the classroom and laboratory. This is why Schmidt was in Nepal making kilns and showing biochars properties to the homeless after the earthquake in April, 2015, and why Draper is working with engineering students from RIT to design biochar concrete roof tiles in Nicaragua.

Their goal in Nicaragua: replace the current metal roofing with something that could be manufactured locally, at low cost, hold up in heavy sunlight, keep out the torrential rains and deter animal intruders. The group made a lightweight aggregate of biochar.

Their method: mix all dry ingredients, add water, blend thoroughly, pour into flat tile mold, vibrate to remove air bubbles (an electric sander works well), transfer flat tile to curved tile mold (using a plastic sheet), allow 2 weeks to cure.

- Each tile weighs around 14 to 16 lbs

- The tiles withheld a 210 lb person standing on them

- With two workers, it will take 5 days to make the 224 tiles for one home

- Estimated CO2 saved per roof is ~400 lbs

During our workshop here at The Farm last week we made char-crete with various biochar concentrations. We made composites by melting styrofoam and soy-foam packing peanuts and the kinds of clamshell containers they use for take-out in restaurants (and typically wind up in rivers or the ocean). We made chardobe brick and compressed CINVA ram brick. We made grout for a tile bench. These exercises were a tiny drop in the ocean of what is required to remove carbon from the atmosphere, but they showed the potential.

By melting extruded polystyrene foam packing peanuts and clamshell containers — (C8H8)n — in an acetone bath — (CH3)2CO — and adding biochar until it stiffened, we made a char-tile that is light, structural, fracture-resistant, and can be molded to any shape. It could be kitchen tiles, surfboards, iphones, boats or biodomes.

| Biocomposite “ore” from recycled polystyrene |

Reversing climate change may not be as difficult or dangerous as many imagine. The only hitch in this scenario is that paved roads and monumental (concrete and steel) architecture are manifestations of peaking civilizations — arriving with times of high Energy Return on Investment (EROI), typically in double digits for firewood, slaves or whales, and triple in the case of light sweet crude. Pyramids and paved roads do not get built in the trough that follows civilizational overshoot and collapse (forest destruction, slave revolt, whale extinction and fracking).

As we return to the circular economy that pre-existed the Ponzi, we may discover in wastes — think of the oceans of discarded plastics — a new source of wealth, and building materials, we can barely imagine.

| Polystyrene waste at a Japanese fish market, by beth |

Posted by Albert Bates

11 Comments on "Albert Bates: Concrete Solutions"

baha on Sun, 25th Jun 2017 4:21 pm

Not exactly what I meant…but it will do 🙂

Plantagenet on Sun, 25th Jun 2017 4:56 pm

Wonderful work is being done by the Biochar Institute.

Unfortunately it is too little and too late.

Cheers!

Cloggie on Sun, 25th Jun 2017 5:00 pm

A Dutch professor Olaf Schuiling has been promoting for years the “olivine method” of removing excess CO2 from the atmosphere:

https://deepresource.wordpress.com/2017/06/25/prof-olaf-schuiling-has-a-solution-for-the-co2-problem/

You can bind 1.25 kilo CO2 with 1 kg olivine powder and turn it into lime stone. Schuiling’s method has made it into the top 11 of Al Gore’s/Richard Branson’s “Virgin Earth Challenge”

There is more than enough olivine to do it. You can spread in the Outback, Sahara, Gobi, Siberia, Kalahari, etc.

Let’s do the energy transition first, so that no new CO2 gets blown into the atmosphere.

Afterwards we can try to repair the atmosphere.

onlooker on Sun, 25th Jun 2017 5:02 pm

Clog would not massive replanting efforts also be effective?

Cloggie on Sun, 25th Jun 2017 5:22 pm

Onlooker, there are several options that perhaps can be used in parallel. But first we need to stop producing new CO2 as soon as possible. By 2050 that could achieved. India is now contemplating aiming for 2050 as well.

Cloggie on Sun, 25th Jun 2017 5:24 pm

India:

http://www.wwfindia.org/news_facts/?10261/100-Renewable-Energy-by-2050-for-India

http://economictimes.indiatimes.com/industry/auto/news/industry/india-aims-to-become-100-e-vehicle-nation-by-2030-piyush-goyal/articleshow/51551706.cms

Cloggie on Sun, 25th Jun 2017 5:34 pm

But we first need to get rid of that insane 5-seater car model, where most cars are occupied by one person only:

https://deepresource.wordpress.com/2017/06/21/renault-twizy/

Furthermore cars can self-generate energy for short commuting distances:

https://deepresource.wordpress.com/2017/06/23/sion-solar-cell-car/

https://deepresource.wordpress.com/2017/06/23/tu-eindhoven-presents-stella-vie/

Norway is leading the way with e-vehicles:

https://deepresource.wordpress.com/2017/06/24/and-the-winner-of-the-e-vehicle-transition-is-norway/

After 2025 sales of new petrol cars allowed. Holland wants to do the same. India perhaps 2030.

Dredd on Sun, 25th Jun 2017 7:54 pm

I like Albert Bates.

Jef on Mon, 26th Jun 2017 9:15 am

Biochar is not a net gain. It takes energy to produce and most if not all processes have a significant waste stream.

J-Gav on Mon, 26th Jun 2017 10:34 am

I like Albert Bates too. But I’m afraid you’d have to throw some pixie dust into the mix to make these ideas work … (see Jef above).

bobinget on Mon, 26th Jun 2017 10:43 am

Oddly enough, W/O natural gas ya can’t make concrete.

CLIMATE

Emissions from the Cement Industry

BY MADELEINE RUBENSTEIN|MAY 9, 2012 Comments

A single industry accounts for around 5% of global carbon dioxide (CO2) emissions. It produces a material so ubiquitous it is nearly invisible: cement. Cement is the primary ingredient in concrete, which in turn forms the foundations and structures of the buildings we live and work in, and the roads and bridges we drive on. Concrete is the second most consumed substance on Earth after water. On average, each year, three tons of concrete are consumed by every person on the planet.

Concrete is used globally to build buildings, bridges, roads, runways, sidewalks, and dams. Cement is indispensable for construction activity, so it is tightly linked to the global economy. Cement production is growing by 2.5% annually, and is expected to rise from 2.55 billion tons in 2006 to 3.7-4.4 billion tons by 2050.

Manufacture of Cement

Though “cement” and “concrete” are often used interchangeably, concrete is actually the final product made from cement. The primary component of cement is limestone. To produce cement, limestone and other clay-like materials are heated in a kiln at 1400°C and then ground to form a lumpy, solid substance called clinker; clinker is then combined with gypsum to form cement.

Cement manufacturing is highly energy – and – emissions intensive because of the extreme heat required to produce it. Producing a ton of cement requires 4.7 million BTU of energy, equivalent to about 400 pounds of coal, and generates nearly a ton of CO2. Given its high emissions and critical importance to society, cement is an obvious place to look to reduce greenhouse gas emissions.