theluckycountry wrote:This is taken from a peakoil topic referenced below.

Steel, quality structural steel is the key to modern industry. The nub of the topic is that due to copper contamination all the recycled steel will be useless by 2050 and new steel will have to made from virgin iron ore, using fossil fuels. This may sound like bad news, but that depends of which country you live in.

The new processes I mentioned above are for producing virgin steel, fossil fuel free.

There are

methods to reduce copper contamination in scrap steel. However these methods tend to be difficult, expensive, and/or energy intensive so they are not used much now. However a combination of factors will make such methods more likely in the future including: growing steel demand, falling iron ore quality and quantity, increasing copper contamination, and environmental pressures.

theluckycountry wrote:Sorry, no batteries, just the alternator attached to a kickass diesel engine. All these big vehicles run this way now, much more efficient than using automatic transmissions, or God forbid, a clutch and gearbox! Yet this is somehow an Electric Vehicle?

Oh I forgot, you have this strange aversion to anything hybrid. Ok if you want to only look at BEV equipment we can do that. And yes, some of it is for underground. FYI, diesel equipment is used in underground mining as well. However they have to invest millions in ventilation to make it work and even then the air pollution is nasty. That's one of the reasons underground mine companies are transitioning to more EV vehicles and equipment.

“Each year, our Australian operations use roughly 1,500 [million] liters of diesel in over 1,000 pieces of equipment. Over half of this is used in our truck fleets. Electrification is the preferred pathway to eliminate this diesel,” said Anna Wiley, BHP’s vice president for Australian planning and technical functions. Cost savings for electric mining trucks are also higher than initially estimated.

Battery-Electric Mining Trucks

The preference for electric vehicles by BHP, Rio Tinto, and Fortescue does not mean the EV revolution in heavy equipment is complete, however. For one thing, the availability of battery-powered ultra-heavy trucks is an issue. Manufacturers are in the early stages of getting such vehicles into production.

Things are moving forward in the heavy truck industry, however. As CleanTechnica reported earlier this year, Nouveau Monde Graphite and Caterpillar have signed definitive agreements to provide a zero emission fleet of electric mining trucks to support operations at NMG’s Matawinie Mine. Volvo is also providing battery-electric mining equipment to Boliden, a Swedish mining company for its fleet of underground mining equipment.

In addition, the companies will need to expand their electric vehicle infrastructure to support an increase in the use of battery-powered machinery. BHP has already contracted for 1.2 GW of renewable energy, but may need up to four times that amount to meet its future electrical needs as it adds battery-electric equipment.

“There would be some downsides to offset this comparable efficiency advantage from electrification, such as how we resolve long term storage and constraints to mining operations due to power infrastructure,” Wiley said. “However, our view is that an electrified mining fleet is more economic and more achievable than the alternative fuel sources.”

BHP is developing what may become the world’s largest potash mine in Saskatchewan, Canada, and plans for 80% of the underground mining vehicles at that facility to be battery-electric.

Australian Mining Companies Chose Battery-Electric Over Hydrogen Fuel Cell Mining TrucksWhile you may notice more electric vehicles on the road today than ever before, the technology is now making its way to miners, the companies extracting the critical minerals needed to build EVs, ensure adequate global food supply, etc.

Snow Lake Lithium outlined its plans in February to develop the world’s first all-electric lithium mine, one of the most critical minerals used to build EV batteries. The mining company’s CEO said at the time if you are going to mine for these resources that will be used to protect the environment, then obtaining them must also be done in a sustainable matter. The company is working with Meglab, an electrical equipment provider and mining solutions company, to make the dream a reality.

Miners using electric vehicles can significantly reduce the heat and carbon exposure they typically experience with diesel-powered equipment. Furthermore, EV mining technology can cost less as it requires less ventilation and cooling.

Miners are cutting CO2 emissions in half by switching to electric vehicles for extracting critical mineralsMining industry has long been powered by diesel, but that’s changing.

Canadian mining companies are starting to cast aside the diesel-powered trucks, loaders, and drills that have long-been the backbone of the industry for electric alternatives — a move that some industry experts say could make mining safer and less polluting. Mario Santos, mining director for Unifor, Canada's largest private sector trade union representing 9,900 mining and smelting workers, said he welcomes the shift. "I think it's a positive change. It's better than the processes we were using before," he told CBC News. For workers who spend their days operating heavy-duty machinery deep beneath the earth's surface, this switch would clean up the diesel-filled air they breathe day-in and day-out. Electric equipment has been slowly trickling into mines for over a decade.

North American mines started testing out heavy-duty electric equipment — mainly vehicles attached to electric trolley lines — in the 1990s. But, Canada was one of the first countries to introduce battery-powered electric vehicles to mining in 2012. Now, after nearly a decade of use, the technology is proving its worth and hesitancy is dissipating, said Rakochy. He's seeing more mines interested in going electric. "We will have more mines coming on stream with battery-electric vehicle technology almost monthly now as we go through the years."

Two recent Sudbury, Ont., mining projects have gone the route of full electrification, and other mines in Saskatchewan, British Columbia and Quebec are in various stages of implementing electric equipment.

Most mines use complex ventilation systems — that can cost anywhere from $20 million to $400 million to install, and often require millions more per year to maintain — to regulate diesel emissions levels underground, said UBC's Madiseh. "Diesel particulate matter — DPMs — are a huge concern, and the main reason you have ventilation in a mine is to dilute the diesel emissions," By contrast, electric equipment doesn't produce fumes, which means companies don't have to spend as much on expensive ventilation. For Rakochy, the difference in air quality between mines that use diesel equipment and those that have electrified is stark. "This will be a bit crude, but you generally will get up and you'll blow your nose. When you blow your nose, your Kleenex will be full of black soot," Rakochy said. "You know that stuff has definitely gone into your nose and into your lungs. With battery-electric vehicle equipment, there's absolutely zero of that."

Is the future of mining electric? As mines transition equipment, new risks emergeEpiroc has won a large order from Glencore in Canada for battery-electric equipment and automation solutions that will be used at what will be one of the world’s first all-electric mines. Glencore’s Sudbury Integrated Nickel Operations has ordered a full fleet of battery-electric equipment for use at the Onaping Depth Project in Ontario, Canada. The nickel and copper mine is located below the existing Craig mine and is being developed to start production in 2024. “Glencore is taking a major leap forward in the mining industry by going all-electric with its Onaping Depth Project. We are excited to collaborate with Glencore and deliver battery-electric vehicles and automation features on their journey to build a mine of the future.”

Traditionally, mining machines are diesel powered, though more and more mining companies are adding battery-electric machines to their fleets. The benefits with battery electrification are significant, including eliminating emissions in operations, reducing noise pollution, and lowering costs by lessening the need for ventilation and cooling when required; this is especially important as underground mines keep getting deeper. The 23 machines ordered include Scooptram loaders, Minetruck haulers, Boomer face drilling rigs, Boltec and Cabletec rock reinforcement rigs, and Simba production drilling rigs.

Epiroc wins equipment order for new all-electric mine in CanadaAt the Borden Gold project near Chapleau in Ontario, Newmont has replaced all of its underground diesel fleet of trucks with Battery Electric Vehicles, making it one of the first all-electric underground mines in Canada. This ambitious plan will not only make the future mine more operationally efficient, but it will improve its health and safety performance and reduce its environmental footprint. Newmont teamed up with Sandvik Mining and MacLean Engineering to provide the battery-powered vehicles for almost all of the mine’s requirements. The new technology will range from battery-operated drilling and blasting equipment, to electric bolters, personnel carriers and, ultimately, a 40-metric-tonne battery-powered haul truck. This will eliminate all GHG emissions associated with the movement of ore and waste rock.

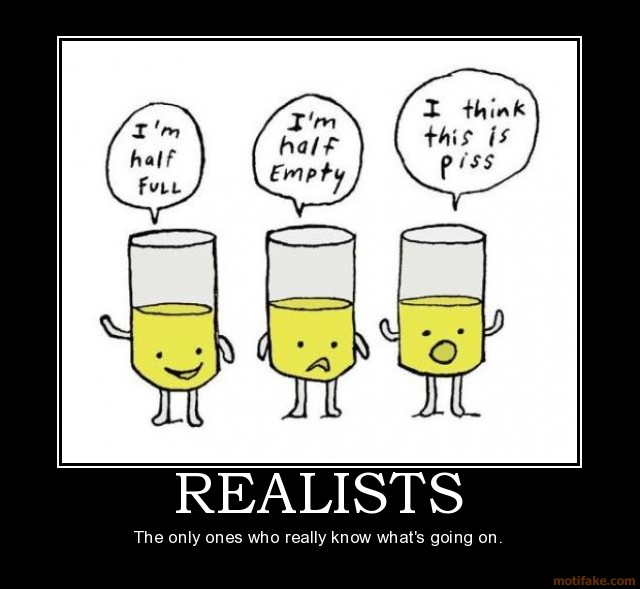

Newmont’s All-Electric Borden MineThe oil barrel is half-full.